01 Our Services

Introduction

understand more..

product

understand more..

Actual performance

understand more..

02 About Us

Founded 43 years

Since the founding of the People's Republic of China in 1993, our company has been specializing in the repair of cranes and related engineering improvements. We are committed to the production and improvement of components and have won many patents and standardized and localized them.Professional license

We are affirmed from all over the world, won a number of patents, and standardization, localization, the goal is to stock, shorten the preparation time for the project, back to the industry.We work hard to improve your productivity

The support and affirmation of the industry is the driving force for the company to continue research and development, let us work together to provide you with the safety and automation related engineering services.

03 SOLUTIONS

Spring Cable Reel

Part 1 Spring Cable Reel

Definition of our type

l KCRS1、KCRS11

l Sheave Guide Chart l Bracket Chart

Specification and Dimension

l KCRS2W、KCRS3W l KCRS4F、KCRS4W、KCRS5F、KCRS5T、KCRS6T

How to choose your type

1. Cable's diameter should be smaller than flange's.

2. Cable weight (per meter) X Length < Maximum reel torque

Example:3.5mm/4C as Cable Dim shows 0.41 kg/m, 10m x 0.41kg/m = 4.1 kg<(7kg)

Cross-refer the specification (P.5) find the choice is CRS 216W.

Reel mounted on the moving equipment will be an effort-saving way.

Design(Cross-refer Questionnaire)

Definition

Example

Efficient Winding Force(kgf)

Max Winding Force

Max Efficient Winding Force Fe(kgf)=μ.F(kgf) μ=0.7

When quantity of poles is over 4 or speed is over 40 m/min or other resistant cause occur, by all means add the buffer (reduce the μ Efficient Value)

Cable Dim

Spring cable reel installation

Step

1. Power-in terminal enter "D" slip ring until through "G" hollow axis, connected with "E" slip ring. (chart 1)

A : 〇Cable Hole

B : Cable Fixed Flake

C : Cable End

D : Slip Ring Unit

E : Slip Ring

F : Carbon Brush Base

G : Axis Located Screw

H : Axis Located Screw

2. Cable pierces "A" hole 〇 from the inside of the roll plate and through "B" fixed point into "C" cable end. Connect the cable with carbon brush and

arrange the cables. Lock the outside cap after connection. *To avoid cable hooking the screw parts, cables in the spring ring unit should be leaned

aside as possible as you can.

3. Roll all cables clockwise in the roll plate (chart 3), or handle the cable and move roll plate anti-clockwise till all cables completed. (chart 4)

4. Locate the cable reel.

5. Move the plate 2~3 cycles (snail shape spring will save the kinetic energy). Pull cable out through the sheave guide; make a trial run after connect

power.

6. When the spring loses its elasticity, repeat the step 5.

7.

Moving cart roll horizontally Moving cart on ground

with sheave guide (not recommended due to the addtional kinetic friction)

(Recommended standard way)

l Performance

-Spring Cable Reel-

For Glass Factory Vacuum Suction Cups For multi-function hoist equipment in precast Cement Factory

Avoid fixingthe electric door, only I-beam needed to suit For Steel Factory: Moving Cart

For Gate Door Opening For Civil Engineering

Motor Cable Reel

Part 2 Motor Cable Reel

Definition of Our Type

T20 Motor Cable Reel

Application: Cable Dim 14mm2~38mm2, Horizontally Furl Length 50M~100M, Vertically Furl 30M. It is suitable for kinds of automatic assemble line.

l Specification

l Type Choice Reference (Horizontally Furl)

l Type Choice Reference (Vertically Furl)

T20H-1308~1314 Adopted When Vertically Furl Cable Dim 8mm2 x 4 pole~14mm2 x4 pole length in 30 M.

l T20、T20.1 Control Panel Explanation

T20.1 T40 Motor Cable Reel

Application: Cable Dim 22mm2~100mm2, Horizontally Furl Length 50M~160M, Vertically Furl 30M. It is suitable for flexible designand special format .

Made-On--Demand

l Specification

l Type Choice Reference (Horizontally Furl)

l Type Choice Reference (Vertically Furl)

T20.1H-1522~1538 Adopted When Vertically Furl Cable Dim 22mm2 x 4 pole~38mm2 x 4 pole length in 30M.

l T40 Control Panel Explanation

M10 and M15 Motor Cable Reel

Application : Cable Dim 5.5mm2~14mm2, Horizontally Furl Length 50M~100M.

For Low Noise And Thin Cable With Many Poles.

l Specification

※Remark: KCRM-M15S-0914 Maximum Horizontally Furl Length is 100M.

M50 Motor Cable Reel

l Maximum Furl Length 200M With Cable Dim 60mm2

Maximum Furl Length 100M With Cable Dim 100mm2

l Application: Heavy Duty And Thick Cable

-Motor Cable Reel-

CSBC Gantry Crane Motor Cable Reel Moving Cart Motor Cable Reel

Tunnel Access 200 Ton Gantry Crane Fei-Tsui Reservoir Hydrology Measurment

Dragon Steel Factory Grab (Vertically 30 Meters) For Agriculture: Watering Can

CSBC: For Moving Cart Civil Engineering: Cable In The Reinforced Concrete Box

Features

Features of KBK Light Rail System

1. Smooth Operation With Low Noise

KBK’s trolleys, consisting of durable bearings, travel with low noise and little friction, and do not generate iron scrap or leak oil. Universal joints of the clamps make crane operation smooth and agile.

2. Time-saving 3 Axis Movement

KBK's 3 axis movement makes it a time-saving tool for a variety of factories, such as motor factories, clean room factories, logistic factories, and factories requiring efficient movements of materials or components.

3. Simple Installation

KBK light rail system is designed to be connected with bolts and latches. With basic tools like hex wrenches, open-ended wrenches, and a level, one can easily complete the installation.

4. High Adaptability

KBK light rail system can adapt to a wide variety of locations, such as general factories, residence, and temporary constructions. It can be directly installed onto ceilings, RC beams, H-shaped beams, and flat or pitched roofs.

5. Great Flexibility

KBK light rail system can easily meet the needs of workplaces by extending or shortening vertical and horizontal beams.

6. Excellent Adjustability

The excellent adjustability of KBK light rail system makes it perfect for workplaces with height limitation or unparalleled vertical beams (see illustration below). Compared with traditional overhead cranes, KBK light rail system is much more ideal for small and medium sized factories.

7. Easy Disassembly and Reassembly

KBK light rail system can be easily disassembled and reassembled, saving extra investment costs in case of relocations of factories or production lines.

Assembly Drawing

KBK light rail system assembly drawing

1 Suspension Bracket (200,250,300)

2 Suspension Socket

3 Suspension Clamp

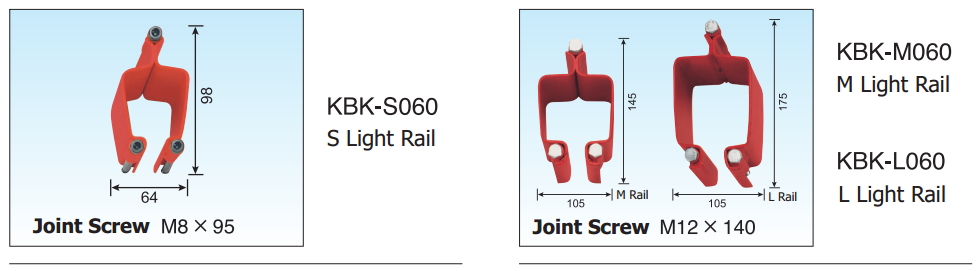

4 KBK Light Rail (KBK-S, KBK-M, KBK-L)

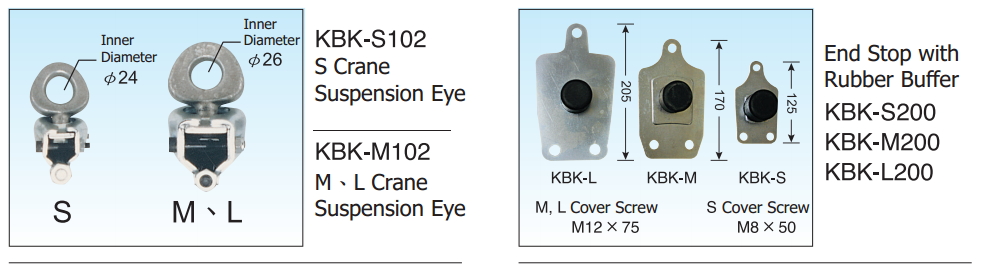

5 KBK Trolley

6 Suspension Eye

7 Joint Socket

8 End Stop

9 Cable Clip

10 Cable

|

Description: |

|

Assembly Type

KBK light rail assembly type

l Single Rail

l Double Runway Rails and Single Bridge Rail

l Double Runway Rails and Double Bridge Rails

Application

KBK Light Rail System Application Example

|

l KBK Pillar Jib Crane |

l KBK Wall Mounted Jib Crane |

|

l KBK Rail Changing System |

l Cross with Twin Bridges |

|

l Curved Single Rail |

l Cross with Single Bridge |

Transportation System

KBK Transportation System

|

L KBK Transportation System Types: |

|

We provide below series of product. Please click the blue texts to link further details.

05 Contact Us

skype:taiwan.kyec

Head office

TEL:+886-3-328-7888

FAX:+886-3-328-0770

Address:No.6, Ln.65, Dinghu 2nd St., Guishan Dist., Taoyuan City 33378, Taiwan

Taipei Service

address:103 台北市大龍街22巷2號

Taichung Service

phone:04-2358-0075

fax:04-2358-2646

address:407 台中市西屯區安和路10-2-3號

Kaohsiung Service

phone:07-384-5997

fax:07-380-8729

address:807 高雄市三民區灣中街81號

Shanghai Service

phone:+86+21+5954-8109

fax:+86+21+3996-8369

address:上海市嘉定區家塘公路600弄19號

Thailand Branch

K.POWER INTERTRADE CO., LTD.

phone:034-861-055

fax:034-861-056

address: 42/6, Moo 2, Khok-Krabue, Muang Samutsakhon, Samutsakhon 74000

E-mail:k.power_kyec@hotmail.com

Indonesia Agent

PT. INDOPUTRA PERDANA

Phone: +62-21-5830-3130

FAX: +62-21-5830-1136

Address: Perkantoran Grand Puri Niaga K6 No. 5D-E Jl. Puri Kencana, Kembangan, Jakarta Barat

Email:suhardi@indoputra.co.id

Website: www.indoputra.co.id

English (UK)

English (UK)  Thai ไทย (ภาษาไทย)

Thai ไทย (ภาษาไทย)  繁體中文

繁體中文  简体中文(中国)

简体中文(中国)